Renowned for our

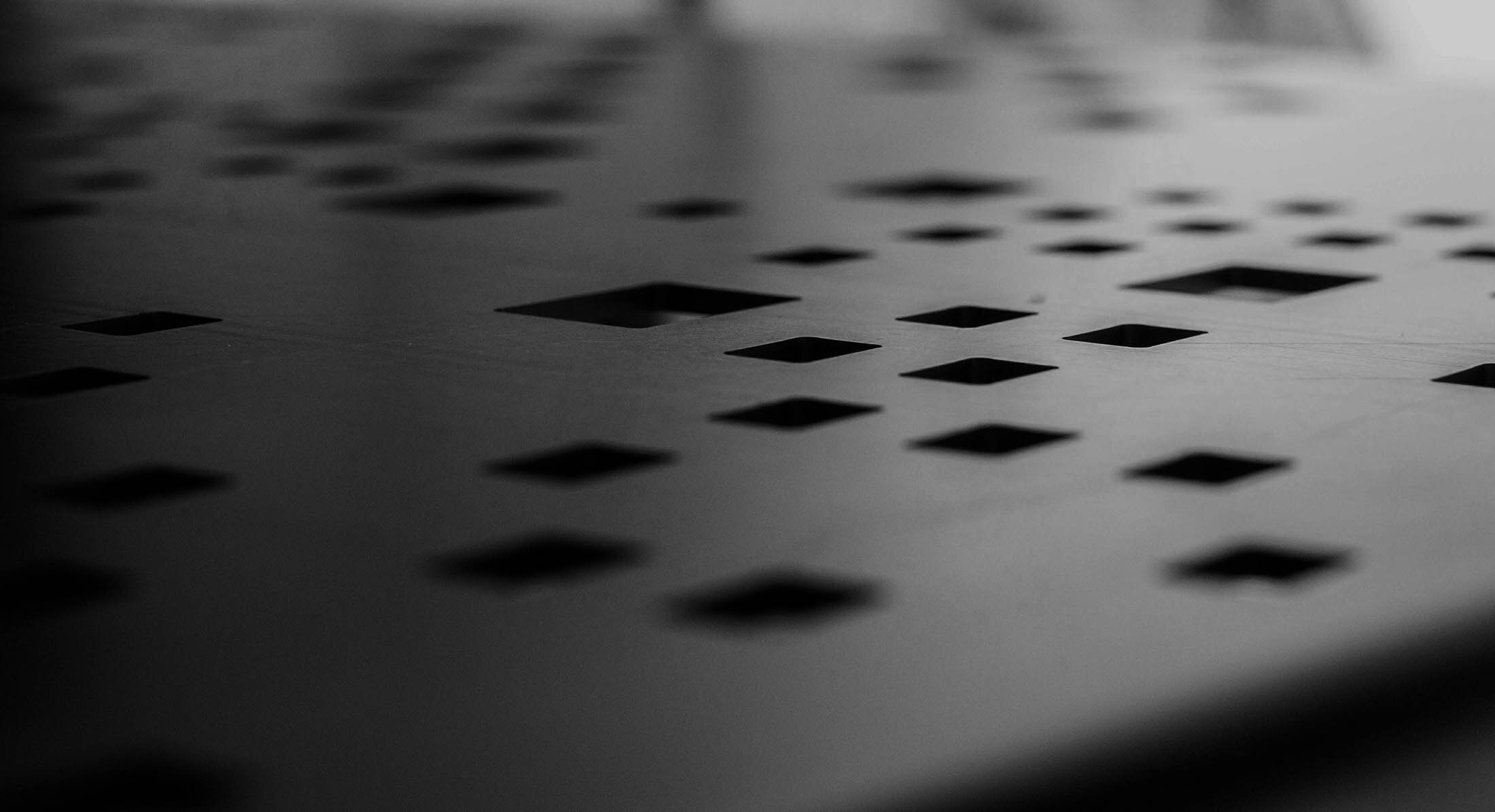

quality and craftsmanship.

What exactly we can do for you?

Probably more than you'd expect. We can design, engineer and manufacture a wide range of mashrabiya and architectural metal works solutions. Always tailored to your specific needs.

Our clients want to enhance the beauty but also the functionality of new building and spaces. That's why they hire ABIYA. Because they know that we offer a variety of engineering solutions that cover their architecture needs.

Our Mashrabiya screens and Metal Works can be used in commercial or residential spaces. And they serve many purposes. Whether it's to provide ventilation and natural lighting. To bring shade to outdoor spaces. Or as inserts for balconies, space dividers or window screens. Or simply to ensure privacy.

Design

-

From concept creation to prototype to production. This includes Mashrabiya, Fretwork, Jali and Decorative Screens tailor-made to client specifications.

-

100s of ready-made mashrabiya patterns available.

-

Designs perfect for both commercial or residential spaces.

-

Mashrabiya screens produced in varying scales, shapes, and thicknesses.

Engineering

-

Meticulously engineered and in-house quality-checked Mashrabiya solutions.

-

Access to our technical knowledge free of charge.

-

Abiya's engineers can help you choose the right materials, thickness, size, and structural support for your project.

CNC Work

-

We have more control over the production process and lead times by keeping our production in-house.

-

We can handle CNC cutting orders of all sizes at our world-class manufacturing plant.

-

Competitive pricing, speedy delivery and the finest quality Mashrabiya panels you can find in the Middle East.

Manufacturing

-

Complete industrial design and manufacturing service for Mashrabiya screens.

-

Cutting, Bending, Testing, Welding, Grinding, Coloring. Anything related to the Mashrabiya production process, we handle it all.

-

Successfully completed world-class projects. Including Jumeirah Hills Development, Rixos Saadiyat Island, Dubai Hills Estate or Mall of Oman.

Coating

-

Choose from over 200 finishes for tailor-made Mashrabiya, Fretwork, Jali and Decorative Screens.

-

Varied color choices.

-

Quality warranty: color stable and resistant to UV. Holds color for 10 years.

Installation

-

We send our in-house specialized team to handle all installation works. If you prefer, you can choose to use your own installation team, under ABIYA's supervision.

-

You can expect: Fast execution, cost savings for contractors and first-class workmanship.

Looking for something else?

Talk to us. For an industry expert and a specialist manufacturer.

Email at contact@abiya.ae. We'll be happy to learn more about your project.